Clutch

What is Torque Spring Washer

What is Torque Spring Washer

Foreward

The applied examples provided here do not mean all the vehicles are designed in the same way, readers need to have their own judgment for reference.

How is its function?

It called Torque Spring Washer, its functions including:

- Low friction coefficient washer, making the movement (open) of the driven pulley more easily.

- Being a washer between two bodies, reducing the wear.

Basic introduction

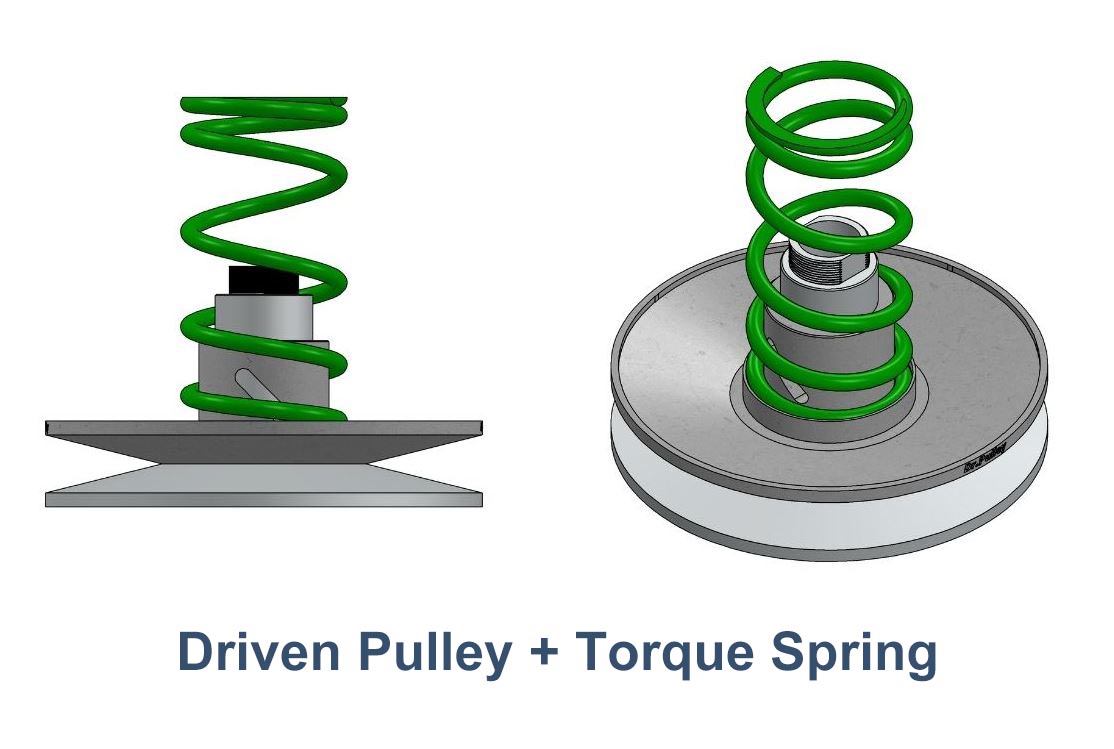

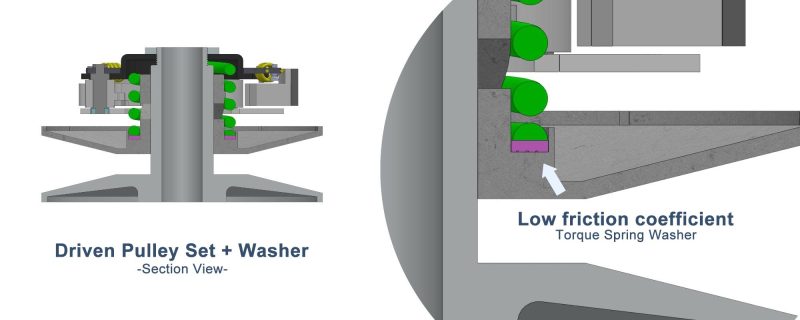

This is a driven pulley, half of which is moveable (back and forward) and rotate with a certain angle, open/close.

This is a torque spring, moving back and forth according to the opening and closing of the driven pulley.

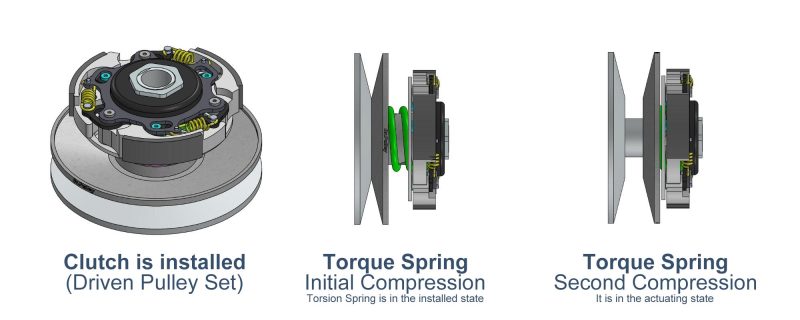

When the clutch is installed completely, the torsion spring is in the installed state, called initial compression or preload compression.

When the rotation speed increases, the driven pulley is actuated (opened), and the spring remains in compression state, it is in the actuating state, and this second compression also called variable transmission compression.

When speed drops, the driven pulley becomes closed, and the spring returns to the installed state. This is one part of the operation of the Driven Pulley

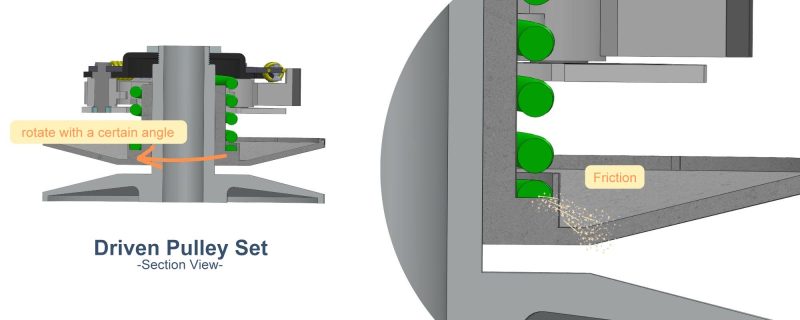

Friction Resistance

When the driven pulley is activated and the moveable driven pulley half is starting to move forward inner side. A frictional resistance will be generated on the contact surface, then these two objects will rub against each other.

In this way, the centrifugal force of the weight roller is not simply used to overcome the compression force of the torque spring, but also be used to overcome the frictional resistance (larger one), so the operation of the driven pulley will have these problems of:

- Need more force for driven pulley operation.

- The speed transmission is not smooth.

- Increased wear.

- The durability of parts adjacent becomes shorter.

When there is it

Washer is installed between the spring housing on the driven pulley and the torque spring, no longer have friction between metal (torque spring) and metal (spring housing on the driven pulley). So the centrifugal force of the weight roller is used to overcome

Spring force + Frictional resistance (Larger one)

become

Spring force + Frictional resistance (Smaller one)

So the new improvement will have

- Less force needed for driven pulley operation

- The speed transmission becomes smoother

- Less wear

- The durability of parts adjacent becomes longer

Are there better WASHERS for selection ?

Dr.Pulley provides many kinds of bearing-grade washers, which emphasizes in self-lubricating properties and oil-free, which helps the CVT transmission shift smoothly and also increase the durability of parts.

Youtube Video

More Information

Our Youtube url : https://www.youtube.com/c/DrPulley

Online Shop : Torque Spring Washer