Variator

Does the bushing of Variator need grease?

Does the Bushing of Variator need grease?

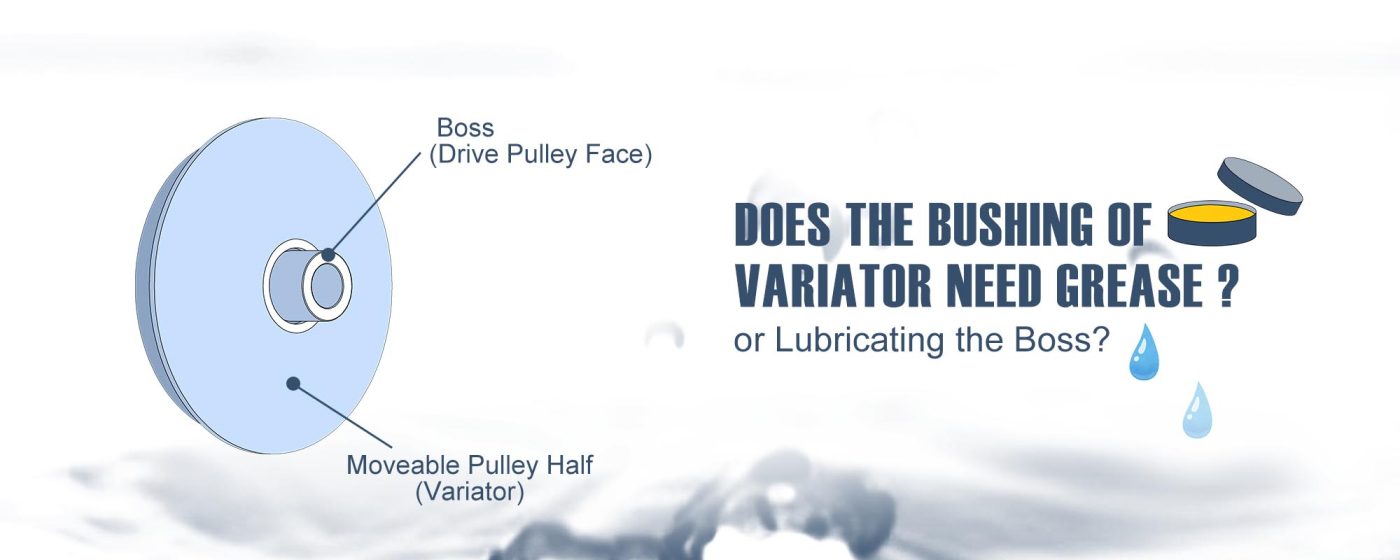

Normally, grease is no need for Variator (Moveable Pulley Half) since the bushing used is one kind of self-lubricated material, In addition, the movement of Variator and Boss (Drive Pulley Face) is synchronous, and the reciprocating back and forth movement is also pretty less.

As the displacement of vehicles increases, the Variator becomes larger, the lateral pressure of the inner bushing increases and the temperature rises. The lubrication from the oil absorbed alone in the bushing is not enough to maintain the “oil film” and the loss of lubricating oil.

In the absence of an oil film, the wear of both the Boss and the Bushing increases, so additional oiling is required at this time to prolong their life.

Where needed to be oil applied?

Ideal grease film

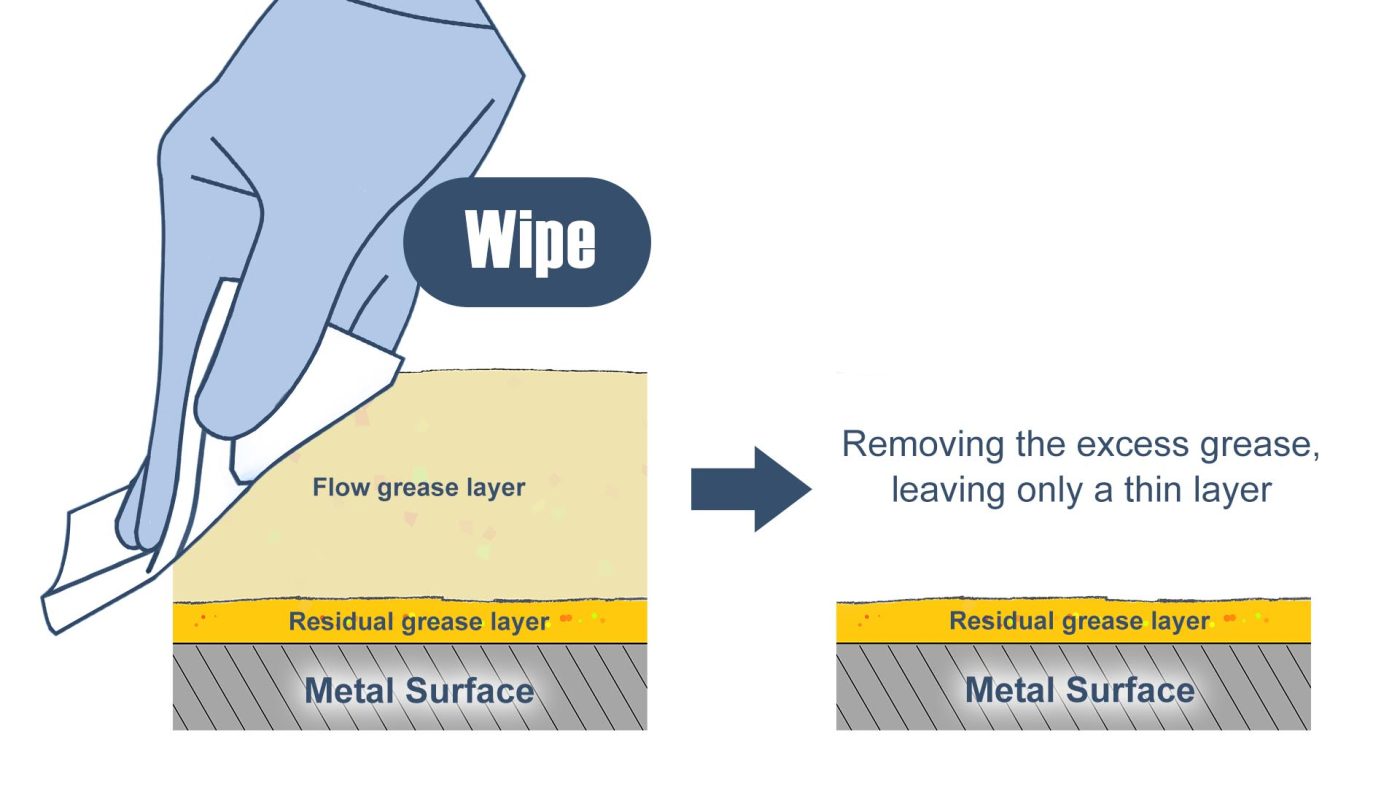

If the grease film is too much, the grease viscosity might become low and be compressed and leaked to the Variator surface when the operation pressure and temperature becomes high.

The grease should be stored only between boundary surface bushing and boss. Otherwise, the grease leakage will make the transmission have problem.

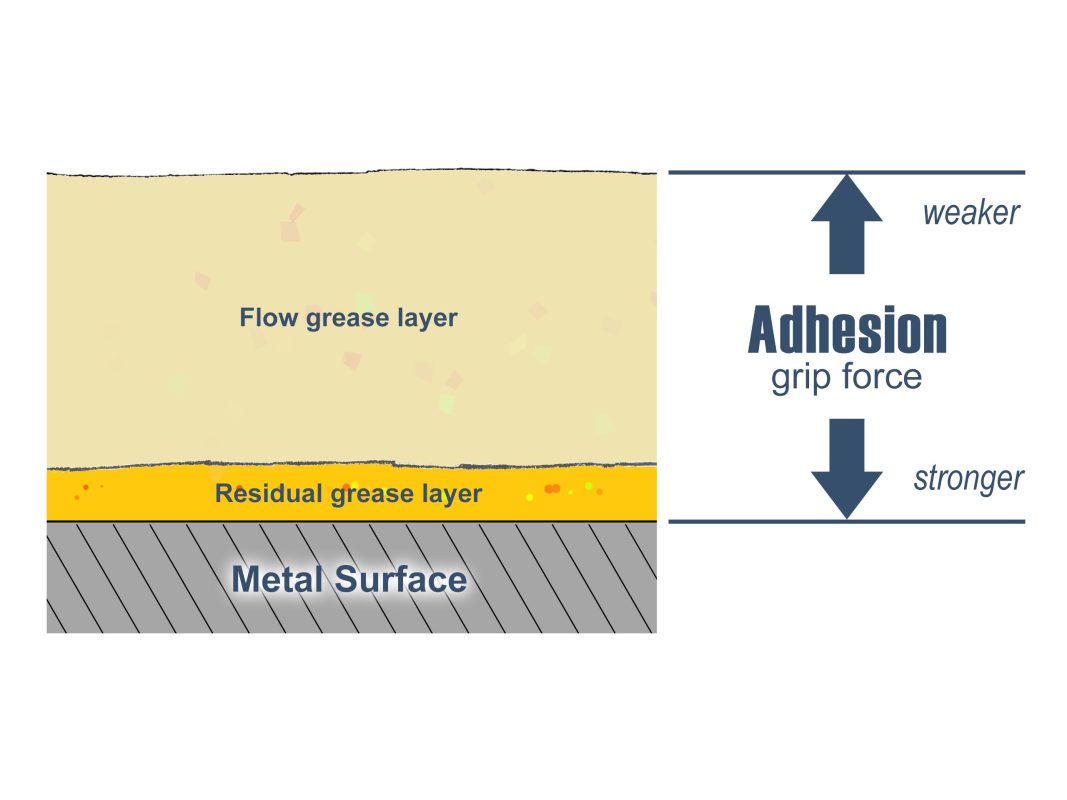

When grease applied, a thin layer will be formed on the metal surface, which is simply divided into two, one is the Flow grease layer, and the other is the Residual grease layer. The schematic diagram is as below.

The adhesion or grip force of grease closer to the metal surface is stronger, such as Residual grease layer.

The adhesion or grip force of grease father away to the metal surface is weaker, such as Flow grease layer.

Therefore, in the bushing of Variator, only the Residual grease layer is an ideal state, or a thin layer of grease as people often say.

How to apply grease?

Adding the grease to the bushing inner surface, spread it evenly with your fingers, and then wipe off the excess grease with a cloth. No need to wipe too much or forcefully. The purpose of wiping is to remove the excess grease, leaving only a thin layer that is almost invisible to the naked eye. You can still feel a smooth Grease film when touch it with fingers.

What kind of grease selected

Choosing high-temperature resistant grease to avoid disintegrating easily

The viscosity of most grease materials will become thin or liquified and flow randomly if their heat resistance is poor. So to choose high-temperature resistant grease is a must to maintain the viscosity stable and without viscosity changing rapidly.

More Information

Our Youtube url : https://www.youtube.com/c/DrPulley

Online Shop : Over-Range Variator Kit

Dr.Pulley Grease, 20g, Multi Purpose (drpulley.co)